-

- 繁體中文 |English

-

TEL:02-29039203

FAX:02-29032558

-

Customer service hours on weekdays except holidays

08:30~17:30

-

-

TEL:02-29039203

FAX:02-29032558

-

Customer service hours on weekdays except holidays

08:30~17:30

-

Desktop Servo Hydraulic Press

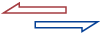

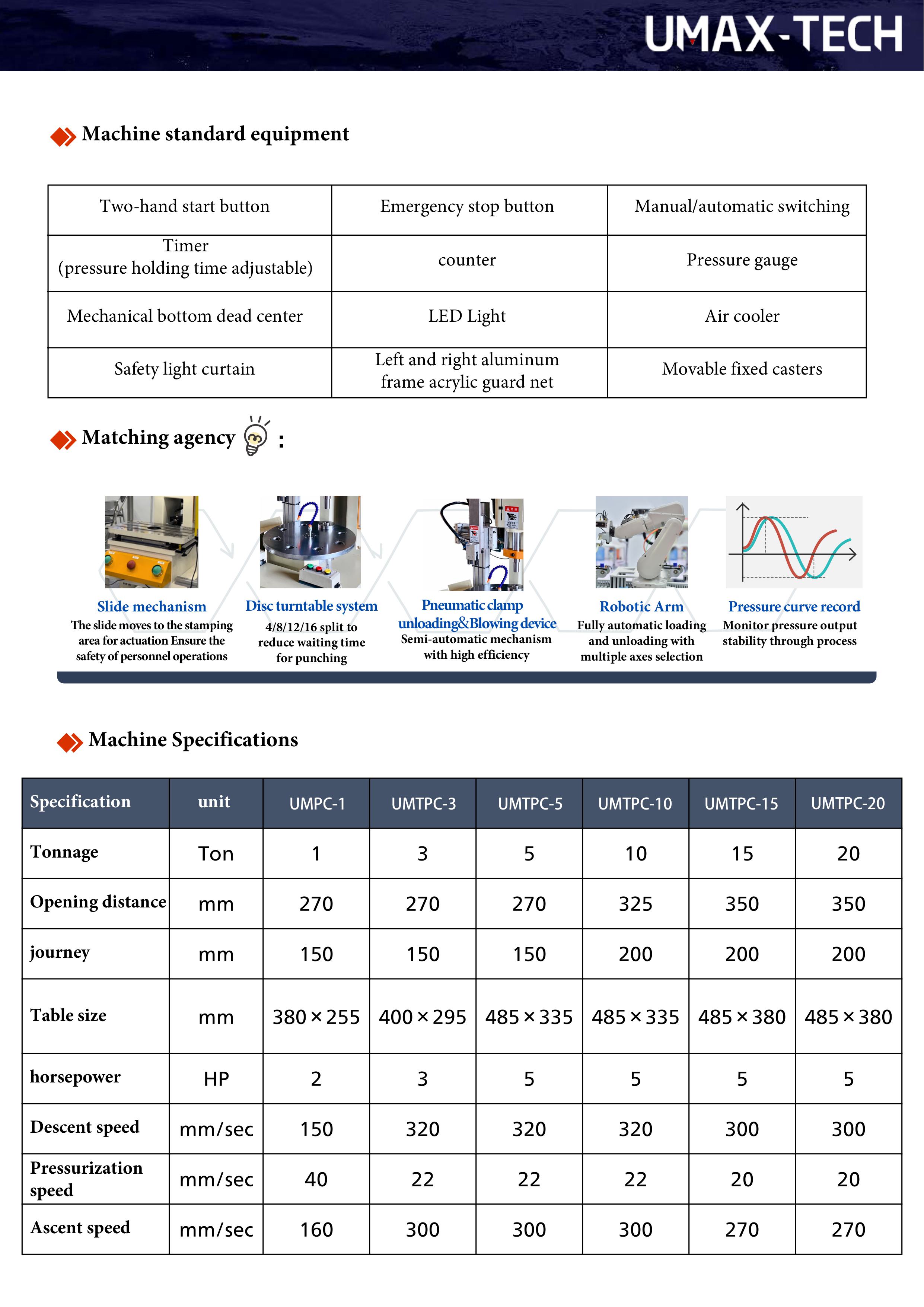

Brand: UMAXTECH Machine Description The machine uses a two-stage hydraulic pressure system with a table-top C-shaped rapid descent and slow pressurization to protect the mold and product, and a through hole is passed through the center of the base to facilitate fixture installation and material movement design and production. Standard specifications: electronic control. Double-hand pressure start. Emergency rise. Manual/automatic switching Timer. Counter. Motor start/stop. Power + power light. Work light. 10. Servo type: (1) 7-inch human-machine interface (can control tonnage, stroke, speed) (2) PLC control system, position scale (3) Digital precision control of speed and pressure values (4) Ensure the punching force and punching stroke each time (5) 99 sets of memory parameters (6) Significant energy saving and ultra-low noise Optional items Front and rear photoelectric safety protection device or PSDI light curtain to start the operating system IE3 energy-saving motor Servo energy-saving motor Automatic oil injection lubrication system Plate removal system (convenient for large mold replacement) Automatic feeding and unloading robot Quick mold change device (Q.D.C) Automatic mold clamping device Press seat hydraulic ejection device Independent hydraulic oil cooler • Punching and shearing buffer Application range of forming machine Punching Cutting Cutting Deep drawing Forging Various specifications are available for inquiry ※Customization: Customization and processing are available ※Delivery time: Products in stock will be shipped within one week